8.7m × 8.7m × 1.9m trolley furnace debugging completed and drying startedPublished by:2023-07-10 Categories:Industry news Viewed by: 690 times The 8.7m customized by Huzhou Dafeng Furnace Industry Technology Co., Ltd. for customers × 8.7m × The 1.9m trolley furnace has been debugged and started drying. The maximum temperature of the trolley furnace can reach 1200 degrees Celsius, mainly used for heat treatment of high-temperature workpiece materials. The high-temperature trolley furnace mainly consists of heating furnace body, trolley and trolley traction mechanism, furnace door and furnace door lifting and pressing device, heating element and fixing device, electric temperature control system, and other parts.  1. The furnace frame is welded with channel steel and angle steel, and the outer shell side plate is welded with Q235 steel plate. The structure is firm and reliable, with good overall strength, not easy to deform, and the surface is flat and smooth.

2. The furnace lining is a full fiber structure, with a total fiber thickness of 400mm. It is a standard type produced by vacuum wire casting method, with a compressed unit weight of ≥ 220Kg/m3; Adopting a scientific and reasonable installation method, this structure is rarely prone to thermal bridge short circuits. It is also made by combining flat stacking and other methods, with good airtightness. It has the advantages of firmness, reliability, convenient maintenance, long service life, light furnace weight, and small temperature rise of the furnace shell. This can effectively prevent the loosening of the lining, improve the insulation performance of the furnace lining, save energy, and reduce production and operation costs. The design and construction method of the full fiber furnace lining are carried out in accordance with the mechanical industry standard "Design and Installation Specification for Refractory Fibers".

3. The seal between the furnace body and the trolley is sealed with a sealing knife. The two sides and tail of the trolley are welded with sealing knives. After the trolley enters the furnace, the sealing knife is inserted into the fiber furnace lining for sealing. The entire seal is a fiber soft seal, with good sealing effect and easy operation.

4. All welding points of the furnace body shall be polished and leveled with iron putty, and then coated with thermal rust resistant paint according to the color code provided by the user. |

|

|

About us |

Product Categories |

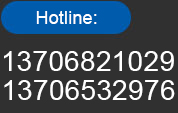

Contact way

|

| Copyright © 2023 Huzhou Dafeng Furnace Technology Co., Ltd all reserved | Web Admin --> >> |