Dafeng brand 120KW bell furnace has been shippedPublished by:2023-07-15 Categories:Industry news Viewed by: 918 times Huzhou Dafeng Furnace Industry Technology Co., Ltd. has completed the manufacturing of a 120KW bell furnace customized for customers. Today, taking advantage of the good weather, we will ship it as soon as possible. We wish our customers good business!  120KW bell furnace base

The bell furnace is mainly used for annealing treatment of cold rolled strip steel, coil elements, coil pipes, alloy castings, exhaust pipes, thin plates, non-ferrous metals such as copper and aluminum, standard parts, silicon steel sheets, etc.

120KW bell furnace loading completed

The bell type furnace consists of a heating cover, two furnace seats, two inner covers, and one cooling cover. The heating cover is made of steel plate and tightly welded, and the furnace lining adopts an energy-saving high-tech full fiber module structure. The furnace top is a full fiber wave stacking high-pressure binding and hanging flat top, with high aluminum screws hanging resistance strips, and a double hole fast cooling door installed on the furnace top. The furnace base is a insulated water-cooled vacuum rubber sealing structure, with a stainless steel air guide base and a high-power vacuum sealing fan. The inner cover is made of stainless steel plate and tightly welded, and the flange and vacuum sealing groove at the bottom of the cover are finely machined and formed by a large vertical lathe. The cooling hood is quickly cooled by dual fan spiral air supply. The vacuum pump is a 2X series rotary vane mechanical vacuum pump. The temperature control cabinet of the bell furnace adopts high-precision automatic temperature control with microcomputer program process curve, and automatically completes the heat treatment process curve. The thyristor is directly controlled by a microcomputer through operation to adjust the power inside the furnace, reducing grid fluctuations. It can automatically change the power size from 0 to 100% based on the furnace loading amount and process slope, achieving highly energy-saving and temperature control.

|

|

|

About us |

Product Categories |

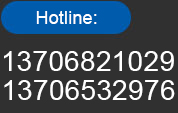

Contact way

|

| Copyright © 2023 Huzhou Dafeng Furnace Technology Co., Ltd all reserved | Web Admin --> >> |